Advantage

Advantage

1.All main electrics are imported, the alternating current contactor is Shilin brand. The switch and button are Taiwan Tend.

2.The air cylinder magnetic valve is imported famous brand, other small magnetic valve is Taiwan brand.

3.Hard tooth gear reducer with well-design structure, low noise, high efficiency and long service life.

4.The mixing shaft is made of nickel & chrome alloy steel. The high abrasion part is additional welded with imported anti abrasion welding rod, then electroplating with hard chrome which is more durable.

5.The main mixing chamber is whole set casting by high anti abrasion alloy steel, after special dealing then electroplating with hard chrome.

6.The anti leakage unit of side wall is made of high-tech material which is wear-resisting and easy to maintain.

7.“M” shape of the pressure gland which make the mixing more thorough and even.

8.The main motor ampere meter is installed in the electrical control panel, under normal running, when the pressure of the mixing chamber is too big, the current exceeds the set value, the connector will automatically adjust the gland’s up and down via the magnetic valve to remit the pressure of the mixing chamber.

9.The mixing chamber is bigger, the diameter of the air cylinder is bigger and gear reducer is also bigger, which enhance the mixing effect,save mixing time and also save the cost.

Main parameter

Main parameter

| Mixing capacity(L) | 35L |

|---|---|

| Motor power | 55KW 6P AC |

| Material feeding | Front/back feeding |

| Temperature adjustment | Steam heating or water cooling |

| Mixing capacity per batching | About 30-40kgs/time |

| Mixing time | 4-8mins/batching |

| Rotor RPM | RPM/RPM |

| Temperature difference | ±5o |

| gear reducer | ZLY-315 |

| Tilting angle | 140° |

| Machine size(mm) | 3200x1900x3000 |

| Machine weight | 6500 |

Public equipment

Public equipment

Power: 380V,50Hz,≧100kw

Air compressor: 6-8kg/cm2 0.5cbm/min

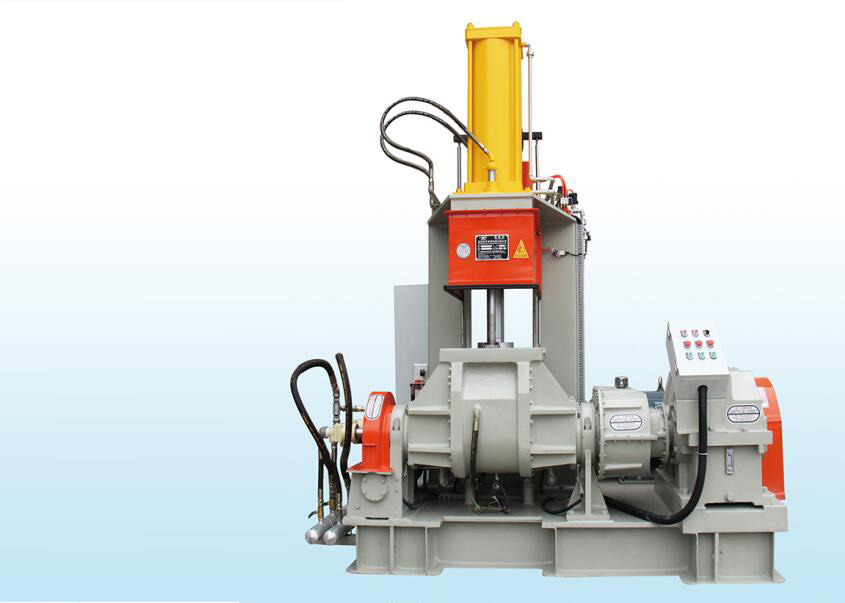

Machine structure

Machine structure

Units

1.Machine base frame: welded by I steel and steel plate.

2.Mixing chamber: is welding by wear-resisting alloy steel,with special design of heating and cooling system.

3.Mixing shaft: the rotors are made of 20crMo forging units, the shaft is made of 20crMo whole set welding. Both rotors and shafts are hollow design which water or steam can get through.

4.Bearing base: made of ZG20 casting steel. Self-aligning bearing.

5.Leakage-proof device: the whole mixing chamber is under special design and also adopts special material.

Pressure device

1.The pressure gland is made of alloy steel,which is designed with small water pipe to cool it. During the mixing,it can provide pressure to the raw material.

2.The air cylinder: with famous good quality sealers.

3.Magnetic valve: Japanese CKD brand.

Discharge device

1.Structure: worm gear structure to discharge the material.

2.Tilting angle: 140degree

3.Tilting motor: 2200W

Transmission drive

1.Main motor: 55kw,6P, AC

2.Pulley belt: good quality rubber belt connect the motor and reducer.

3.Reducer: model ZLY315.

4.Ratio gear: the front and back rotor have speed difference.

Pipes

1.High pressure pipe.

2.The mixing chamber, rotor, pressure lid all with small water cooling pipe. The in & out water pipe size is 1?.

Electrical control cabinet

1.Floor stand electrical control cabinet.

2.Standard electrical supply and device.

3.Hongtai standard electrical cabinet or under customer special request.

4.Automatic temperature setting,reveal and control.

5.Time setting, thermometer, current meter and alarm.